InfraredTeam provides NFPA-compliant thermal imaging inspections for commercial and industrial facilities across the Dallas–Fort Worth Metroplex, throughout Texas, and nationwide. From electrical panels and mechanical equipment to roofing systems, building envelopes, and moisture intrusion, our certified thermographers use advanced infrared technology and detailed reporting to detect issues early—before they lead to costly failures or downtime.

Featured Services

Electrical Infrared Inspections

Detect early-stage faults in electrical panels, switchgear, transformers, and circuit breakers. Our NFPA 70B-compliant inspections help prevent outages, fires, and costly downtime through early detection of hotspots, loose connections, and overloads.

Mechanical Systems Thermography

Pinpoint issues in motors, bearings, pumps, and rotating equipment before they cause failure. Infrared diagnostics reveal overheating, friction, and wear to support optimized maintenance planning.

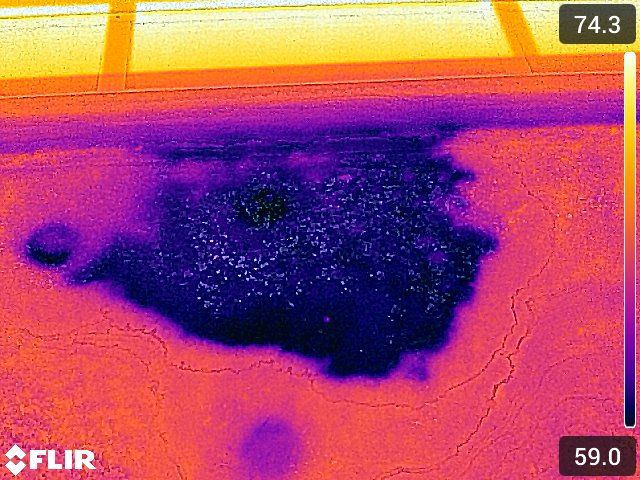

Roof & Moisture Intrusion Surveys

Identify moisture ingress, roof membrane failure, and insulation loss. We use handheld and drone-based imaging to deliver detailed moisture mapping and guide proactive repair decisions.

Drone / Aerial Infrared Imaging

Capture high-resolution thermal data over large rooftops, solar fields, and facility exteriors. Aerial thermography provides fast, accurate assessments with georeferenced visuals and annotated findings.

Arc Flash Studies

Identify electrical hazards and ensure worker safety with NFPA 70E-compliant arc flash studies. We analyze your electrical system to calculate incident energy levels, determine required PPE, and provide accurate labeling to meet OSHA requirements and reduce the risk of injury during live work.

All Services

Electrical and mechanical systems inspections

Preventative maintenance analysis and recommendations

Furnace / refractory inspections

Moisture surveys

Aerial roof assessments

Plumbing systems

Building envelope studies

Sustainability evaluations

Process improvement studies

Construction verification

Why InfraredTeam?

- Independent & Unbiased Analysis: We provide objective thermal inspections and diagnostics—never tied to repair upsells or third-party vendors

- Continual Investment in Technology & Training: We use industry-leading infrared cameras and software, and our team stays current with NFPA, drone, and certification standards

- Fast Turnaround & Clear Reporting: Receive annotated, prioritized reports within days, so you can take immediate action and reduce downtime risk.

- NFPA 70B / 70E Compliance Focus: We help facilities meet thermal inspection requirements for preventive maintenance, electrical safety, and risk mitigation.

- Texas-Based with Nationwide Reach: Headquartered in the Dallas–Fort Worth Metroplex, we serve clients statewide and across the US—supporting single and multi-site operations.

- ROI-Driven Recommendations: Our inspections highlight the most critical findings so you can prioritize actions that deliver the greatest return on investment.

Case Studies

Multifamily Residential

Catastrophic Fire Prevented

-

Client Profile350-unit Class A multifamily complex, constructed in 2023

-

ChallengeBreaker trips and voltage fluctuations in a new residential building prompted management to request a full NFPA 70B-compliant infrared inspection.

-

SolutionInfraredTeam scanned all electrical panels and common systems under full load.

Read more

Multifamily Residential

Catastrophic Fire Prevented

-

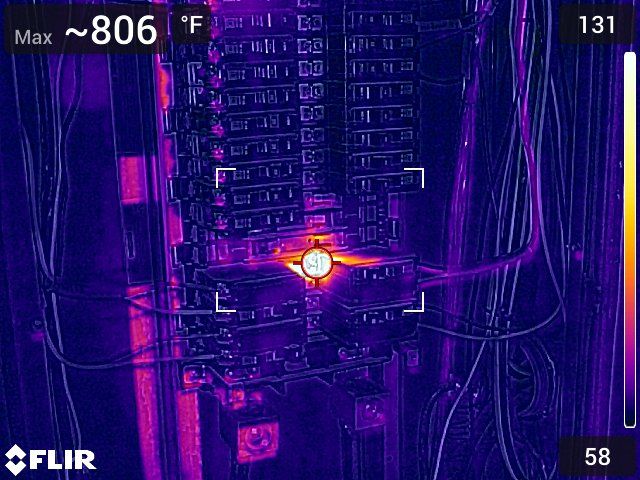

FindingsA glowing 806°F hotspot on a defective breaker that failed to trip—seconds from catastrophic failure.

-

ResolutionBreaker was safely replaced; follow-up confirmed safe conditions.

-

Impact

- $5–10 million in fire damage averted

- No tenant displacement

- Insurance credit potential of 10–15%

-

Key TakeawayA $2,500 thermal inspection prevented a catastrophic loss—delivering major ROI and compliance benefits.

National Distribution Center

Hidden Hotspot in Main Bus Duct

-

Client Profile500,000 sq. ft. warehouse and logistics hub for a national supply chain operator

-

ChallengeIntermittent flickering and breaker resets on a main line prompted concern.

-

SolutionFull NFPA 70B infrared inspection of switchgear, MCCs, and bus ducts under live load.

Read more

National Distribution Center

Hidden Hotspot in Main Bus Duct

-

Findings460°F hotspot hidden in a main feeder lug inside a bus duct—undetectable visually.

-

ResolutionDe-energized during planned downtime and corrected with no production loss.

-

Impact

- Avoided 48–72 hours of downtime (~$250K value)

- Eliminated risk of multimillion-dollar fire

- Retained insurance eligibility and compliance

-

Key TakeawayA proactive thermal scan exposed a dangerous fault invisible to standard checks—preserving uptime and profitability.

Commercial Office Tower

Electrical Issue Resolved in Hours

-

Client Profile20-story Class A high-rise managed by a global commercial real estate firm

-

ChallengeHVAC issues tied to electrical faults were disrupting tenant comfort and operations.

-

SolutionInfraredTeam scanned all panels, switchboards, and electrical rooms.

Read more

Commercial Office Tower

Electrical Issue Resolved in Hours

-

FindingsLoose neutral connection running 220°F above normal.

-

ResolutionFixed immediately during same-day maintenance window—no added downtime.

-

Impact

- Saved $15K+ in reactive service and emergency labor

- Prevented 2–3 days of HVAC downtime (~$40K tenant ops)

- Improved maintenance documentation and compliance

-

Key TakeawayQuick, affordable thermography averted major costs and service interruptions.

Sports & Entertainment Group

Nationwide NFPA 70B Compliance

-

Client ProfileU.S.-based entertainment and hospitality brand with dozens of high-traffic venues

-

ChallengeClient needed consistent, compliant inspections across all U.S. sites—replacing fragmented vendor management.

-

SolutionInfraredTeam implemented a national inspection program across 12 sites with standardized reporting.

Read more

Sports & Entertainment Group

Nationwide NFPA 70B Compliance

-

FindingsMultiple moderate thermal anomalies corrected within 30 days by onsite teams.

-

Impact

- 100% NFPA 70B compliance across all venues

- Simplified vendor coordination

- $250K+ annual insurance premium savings

-

Key TakeawayOne nationwide partner delivered consistent reporting, compliance, and cost savings across every site.

FAQs

Is an infrared inspection required by law?

Under the 2023 NFPA 70B standard, infrared inspections are mandatory for most commercial, industrial, and multi-family electrical systems. The standard requires:

- At least once every 12 months for typical equipment

- Every 6 months for high-risk equipment or systems with a history of issues

- While not a federal law, NFPA 70B is recognized by OSHA and widely enforced through insurance and safety compliance. Failing to follow the inspection schedule can lead to denied claims, citations, and increased liability in the event of a failure.

Are your inspections NFPA 70B and 70E compliant?

Yes. Our inspections follow NFPA 70B standards for electrical preventative maintenance and NFPA 70E guidelines for electrical safety. We provide compliant reports that help facilities meet audit and insurance requirements.

Do you provide inspections outside of Texas?

Yes. While our headquarters is in the Dallas–Fort Worth area, we serve clients nationwide and support multi-site operations across the U.S.

What are the benefits of an infrared inspection?

Infrared inspections offer proactive risk detection that can prevent fires, unplanned outages, and costly repairs. Benefits include:

- Early fault detection in electrical, mechanical, and roofing systems

- Insurance premium reductions with proper documentation

- Minimized downtime by identifying issues before failure

- Compliance with NFPA 70B and other preventive maintenance standards

- Improved asset reliability and safety

Can you inspect electrical systems while they’re live?

In most cases, yes. Thermal inspections are designed to be performed on energized equipment to detect heat anomalies caused by load, faults, or loose connections. Our team follows strict safety protocols during every inspection.

How long does an inspection take?

The time required depends on the size and complexity of the facility. A small commercial site may take just a few hours, while larger campuses or data centers may require a full day or multiple days. We’ll provide a detailed estimate before scheduling.

How soon will I receive my report?

Most reports are delivered within 3–5 business days. Reports include annotated thermal images, temperature deltas, prioritized findings, and actionable recommendations.

Need a Custom Inspection Plan?

We tailor our services to your facility’s systems, risks, and reporting needs.