InfraredTeam delivers specialized infrared imaging applications tailored to the operational demands of industrial and commercial facilities across the Dallas–Fort Worth Metroplex, throughout Texas, and nationwide. From aerial roof surveys and refractory furnace scans to moisture intrusion detection and mechanical diagnostics, our certified thermographers help clients prevent failures, maintain uptime, and protect mission-critical assets.

Aerial Infrared Applications

Using drones or manned platforms, our aerial infrared imaging enables rapid, high-resolution assessments of roofs, solar farms, and extensive facility exteriors. Whether you’re inspecting flat rooftops, solar arrays, or large industrial complexes, we deliver georeferenced thermal maps, clear annotations, and prioritized findings for maintenance planning.

Roof & Wall Moisture Surveys

We combine infrared imaging and moisture detection techniques to identify water ingress, insulation voids, and membrane failures in roofs and walls. Early detection helps mitigate structural damage, reduce mold risk, and inform targeted repairs—saving you from costly full replacements.

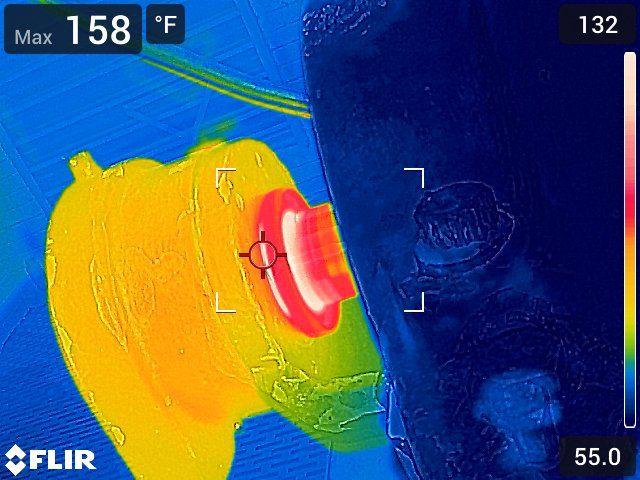

Mechanical System Diagnostics

Thermal imaging of motors, pumps, bearings, gears, and rotating equipment reveals temperature anomalies, friction issues, and inefficiencies. By establishing baseline thermal signatures and trending over time, you can catch failures before they escalate and optimize maintenance schedules.

FAQs

Do aerial infrared scans require ground access?

Not always. In most cases, our drone-operated inspections can be conducted without entering the facility grounds, as long as we have a clear flight perimeter and authorization. For secure or restricted areas, coordination with your site manager ensures safe, compliant flight operations.

Can furnaces and refractory systems be inspected while operating?

Yes. Infrared thermography is ideal for inspecting furnaces, kilns, and refractory linings under normal operating temperatures. This allows us to identify insulation breakdowns, hotspots, and structural issues without shutting down equipment, minimizing downtime and capturing real-world thermal behavior.

How deep can infrared scans detect moisture or leaks?

Infrared can detect surface and near-surface temperature variations caused by hidden moisture, but it does not “see through” walls or roofs. It works best when combined with moisture meters to confirm findings. Detection depth depends on insulation type, material density, and environmental conditions—but typically ranges from a few millimeters up to several inches.

Can infrared detect mechanical issues before failure?

Absolutely. Thermal imaging can reveal overheating in motors, bearings, pumps, and gearboxes well before mechanical failure occurs. By tracking temperature trends over time, we help maintenance teams detect friction, imbalance, or inefficiency—and prevent unplanned outages.

How accurate are thermal imaging surveys for roof and wall systems?

When performed under the right conditions (e.g., dry roof, temperature differential), infrared surveys can be over 90% accurate in locating moisture, insulation voids, or membrane failures. We combine IR with visual inspection, core sampling, or moisture meters to increase diagnostic accuracy and reduce false positives.